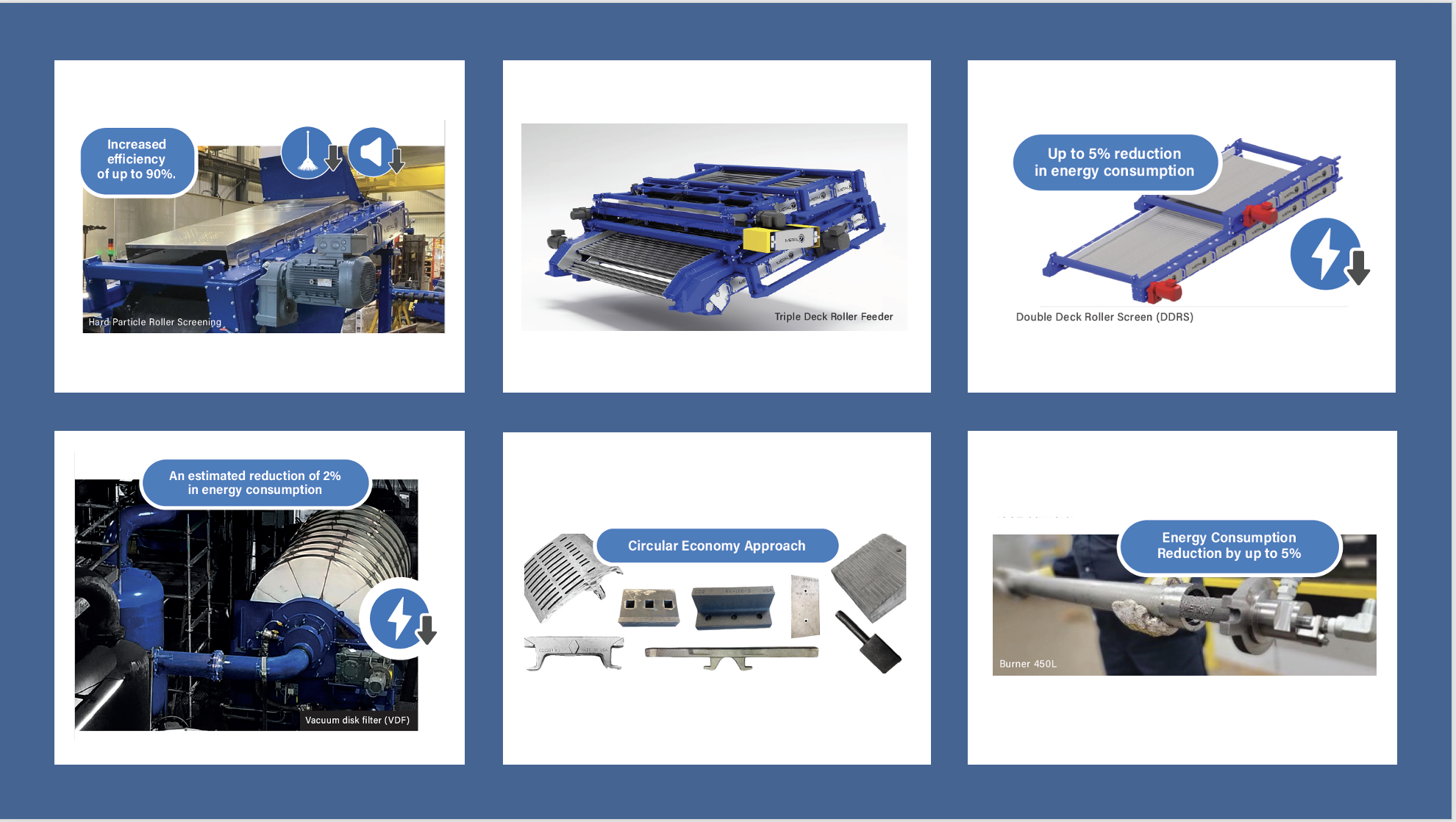

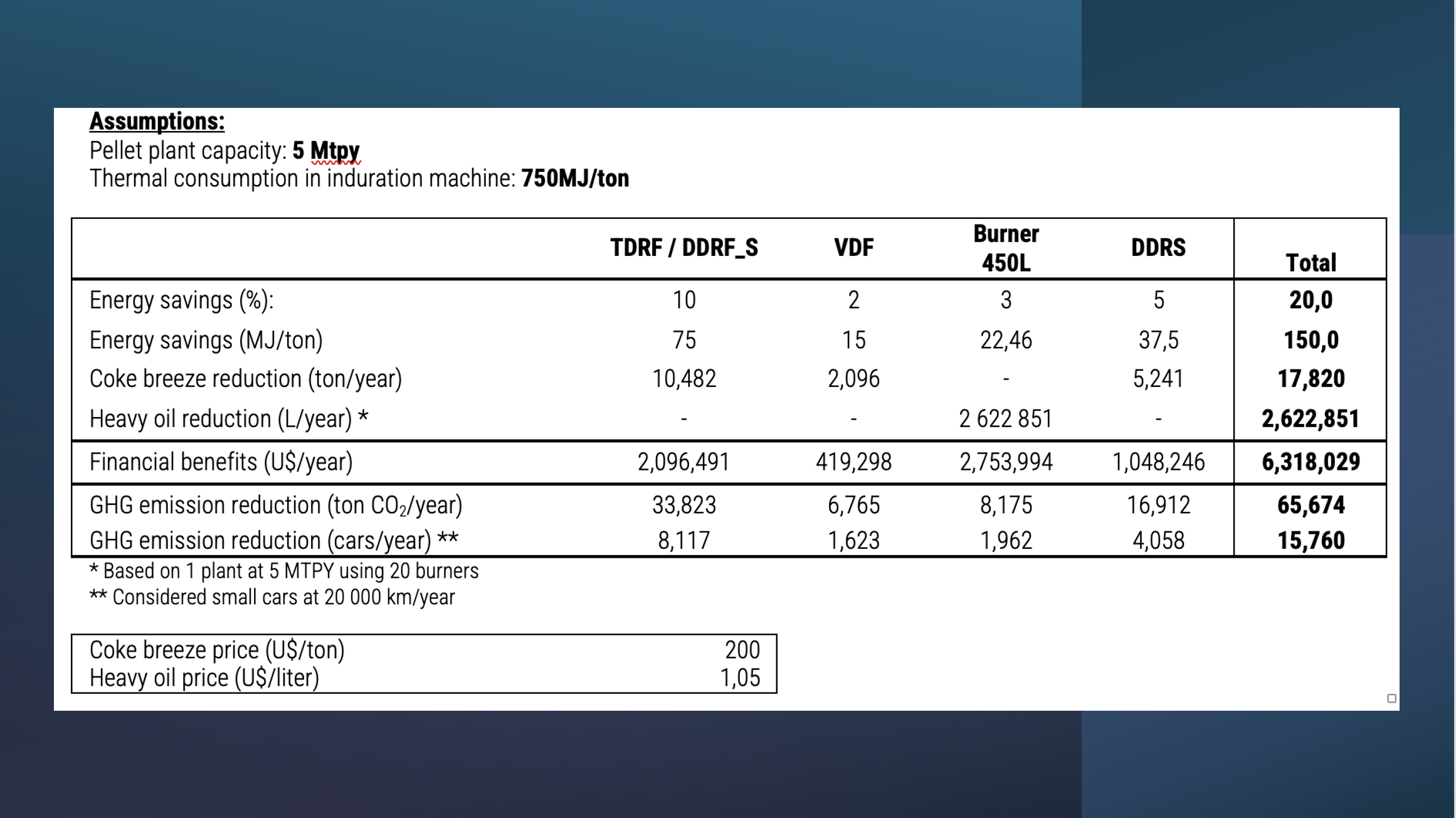

In the ever-evolving landscape of the steel industry, the imperative to curb carbon emissions looms large. As the world unites to combat climate change, every link in the supply chain, including iron ore pelletizing, must embrace sustainability.At Metal7, we’re not just following the trend – we’re setting the standard with our multi-faceted approach to reducing the carbon footprint in iron ore pelletizing. Let’s delve into the groundbreaking advancements driving this transformative journey.1.Filtration: Enhancing Efficiency, Minimizing MoistureOur vacuum disk filter (VDF) is a testament to our commitment to innovation. Designed for enhanced throughput and minimal moisture content in filter cake, the VDF boasts large vacuum filtrate tubes and anti-wear coatings for optimal performance. By reducing filter cake moisture content by 0.5%, we’re not only improving operational efficiency but also slashing energy consumption in the furnace drying zone by an estimated 2%. 2. Screening for Optimal QualityIntroducing the Double Deck Roller Screen (DDRS), a game-changer in plant efficiency. By maximizing the screening area and minimizing recirculation loads, the DDRS ensures optimal pellet quality with a more uniform particle size distribution and enhanced furnace permeability. This innovation brings estimated energy savings of up to 5% and significantly reduces greenhouse gas emissions. 3. Innovative Feeding SolutionsOur patented Double Deck Roller Feeder with Segregation (DDRF-S) and Triple Deck Roller Feeder (TDRF) technologies revolutionize the induration process. By creating a segregated bed profile in the furnace, we optimize energy use and improve firing efficiency. Additionally, our Epsilon chute maintains pellet sphericity, further enhancing airflow and reducing energy consumption. 4. Circular Economy in ActionEmbracing a circular economy mindset, we offer furnace replacement parts designed for reuse throughout their life cycles. Our commitment to sustainability extends to our Burner 450L, which significantly reduces cooling air consumption by up to 70%, leading to tangible energy savings and GHG emissions reductions without requiring furnace modifications. 5. Quality, Dust, and Noise ManagementOur Hard Particle Roller Screening technology improves screening efficiency, reduces noise levels, and minimizes dust generation, enhancing both workplace safety and operational efficiency. At Metal7, sustainability isn’t just a buzzword – it’s ingrained in our DNA. Through meticulous calculations and real-world data, we’ve quantified the environmental benefits of our technologies. From energy savings to CO2 emission reductions, our innovations are propelling us towards a greener, more sustainable future.

In the table, it’s essential to note that the benefits of certain technologies are not cumulative. In other words, if the client utilizes both the DDRS and TDRF, the combined energy savings are unlikely to reach 15%.

|