METAL7

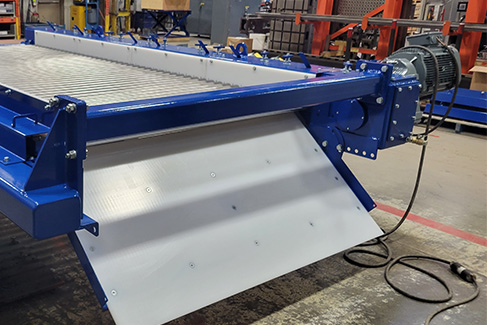

SDRS: Your solution to Remove Fines and Oversized Pellets in the balling circuit.

Experience enhanced pellet screening efficiency with Metal7’s Single Deck Roller Screen, ensuring uniform gap openings, reduced maintenance, and adequate screening area for optimal pellet plant performance.

Motivations

Achieving and sustaining high screening efficiency is a challenge, nevertheless it is essential for an efficient and high-performance pellet plant.

The solution

IMPROVED SCREENING EFFICIENCY

Enhancing screening reliability, SDRS (SINGLE DECK ROLLER SCREEN) utilizes high-quality manufacturing parts to ensure uniform gap openings and minimize re-gapping activities. Equipped with rollers featuring a special wear-resistant coating, it reduces bending effects during operation, maintaining consistent performance.

ENHANCED SCREENING AREA

Our screening devices are available with smaller roller diameters, starting from 55 mm, while optimizing the screening area within the same footprint. The increased screening area enhances the probability of proper pellet screening, resulting in improved screening efficiency.

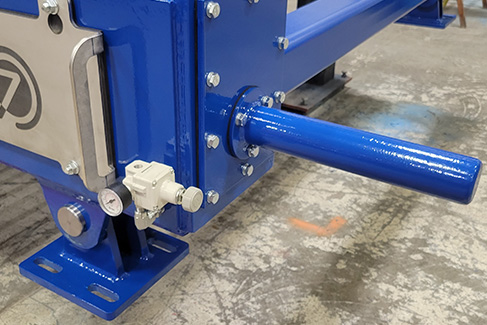

REDUCED MAINTENANCE

Our manufacturing processes use high-quality materials and special engineering developed over the years to ensure fewer maintenance interventions required to keep the equipment in operation. This reduces the need for corrective shutdowns and improves machine availability.

BENEFITS & FEATURES

- Uniform gap openings maintained during operation.

- Reduction of bending (run-out) effects.

- Efficient transport of green pellets through the unit.

- No build-up on the rollers.

- Rollers from 55 mm to 75 mm in diameter are available, increasing the screening area for the same footprint.

- On-size pellets are kept in the final product, reducing the recirculating load.

- Minimal maintenance and fewer shutdowns for re-gapping.

Further information

We understand that some topics may be more complex and raise specific questions that may not be fully covered on our site. If you have more specific questions, special requests or require further clarification, we strongly encourage you to contact us.