Enduride

Optimization Technologies

Advanced technologies designed to enhance the efficiency and longevity of your conveyor systems, minimizing the need for maintenance.

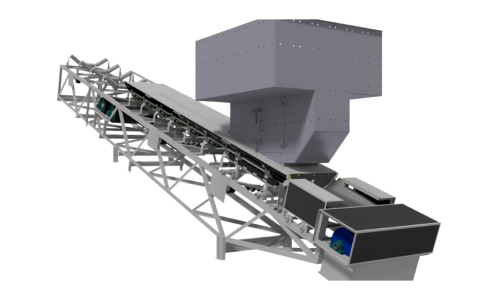

Transpar

Features:

A versatile and effective dust confinement tool for conveyor belts. It combines a deep trough design with external sliding rails and flexible self-adjusting skirts, transforming the conveyor into a dust-tight tube.

Applications:

It can be used at transfer points between conveyors, screens, or crushers and can be equipped with a SPARMAT impact bed to absorb shocks from heavy material.

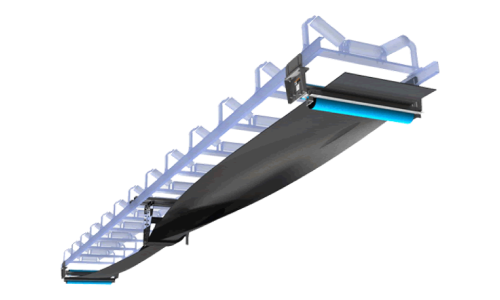

Spar 3 - Belt Turnover

Features:

A highly effective device removing dirt under conveyor belts, reducing carryback by over 90%. It limits cleaning operations on the return side to just two points (head and tail), making it particularly useful in tunnels or other challenging locations. Eliminating build-up on return idlers improves belt alignment and extends the belt’s lifespan. Fewer cleaning operations mean fewer employees in proximity to the conveyor, enhancing overall safety.

Applications:

It can be installed without any particular modification on almost all conveyor belts having a length of at least 40 meters (131 ft). Can accommodate belts from 500 mm to 1600 mm wide (19 11/16 in to 63 in).

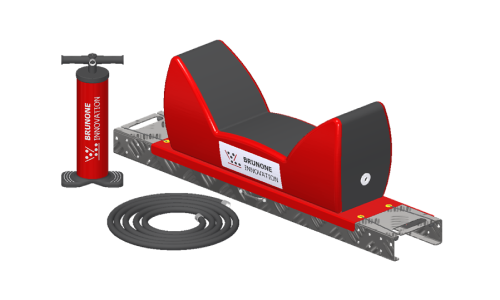

Sparcric G

Features:

An innovative conveyor belt lifting system, used to facilitate the maintenance of the rollers of conveyor belts. The SPARCRIC G inflates using a simple low pressure pump. it fits prefectly for working on 3-roller stations.

Applications:

Marketed for belts on 4 models:

• 500/800

• 1000/1200

• 1400/1600

• 1800/2000

Available on demand for other types of station.