METAL7

Filtration

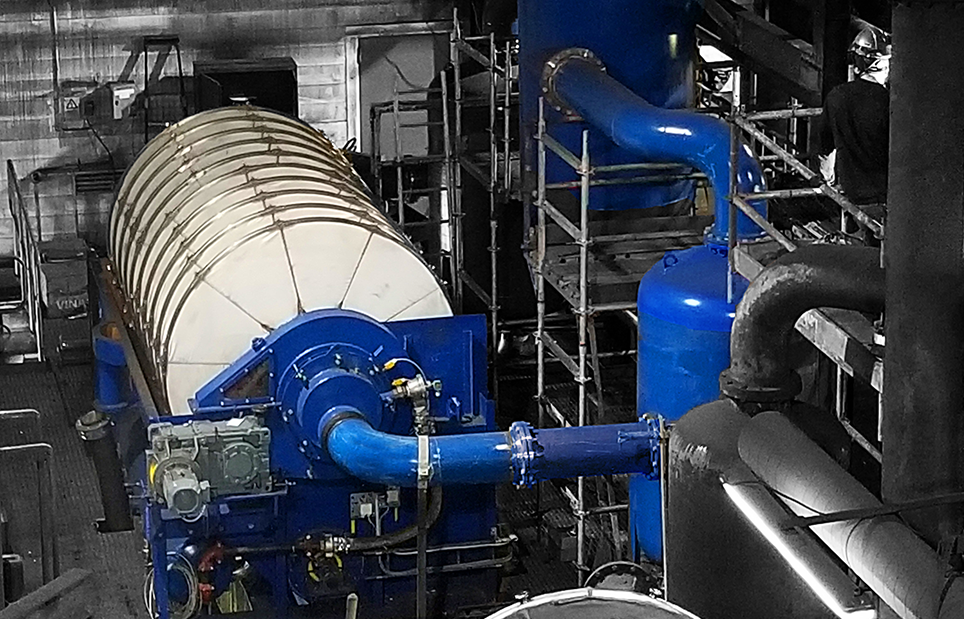

Many ore treatment processes require the dewatering of a slurry, which is of critical importance for iron ore pelletizing plants. After grinding, the slurry must be transformed into a filter cake with minimal moisture content. Our Vacuum Disc Filter technology guarantees high-volume production of low-moisture filter cake, with easy maintenance and a contribution to reducing the carbon footprint of pellet plants.

Vacuum Disc Filter

Our optimized design incorporates the use of thermally sprayed coatings to protect critical components linked to a specific engineering design. The results: higher filtration rates, reduced moisture content and process stability. Say hello to efficient, high-performance filtration with Metal7!

Key Benefits:

- Anti-wear and self-lubricating coatings on critical components.

- Significantly longer service life.

- Minimal maintenance requirements.

- Optimized design to avoid leaks and pressure drops.

- Production of filter cake with constant moisture content, enabling stabilization of the agglomeration process.

- Production of filter cake with reduced moisture content, enabling lower energy consumption on the firing process (drying zone).

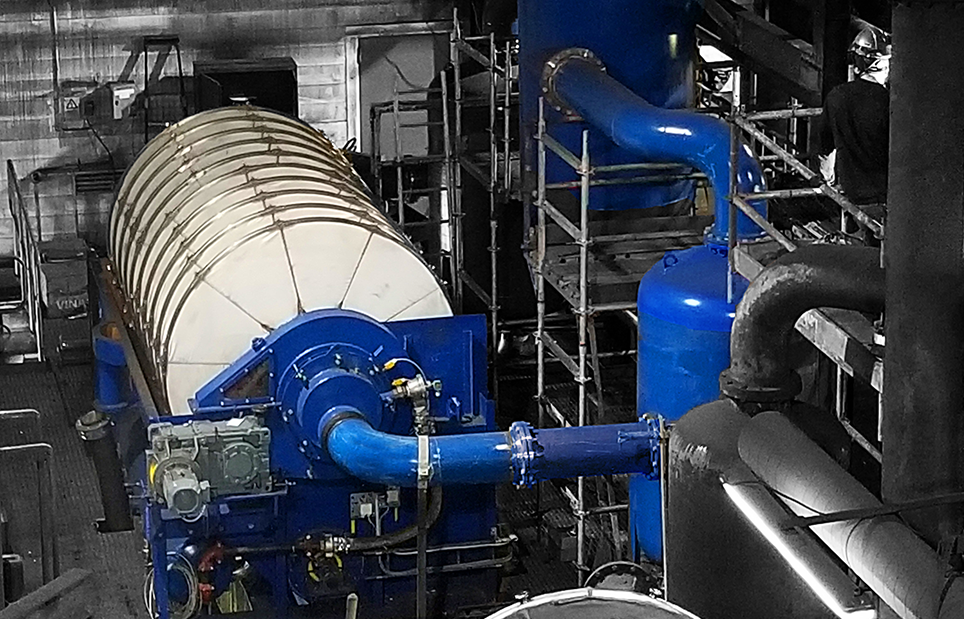

Vacuum Disc Filter

Our optimized design incorporates the use of thermally sprayed coatings to protect critical components linked to a specific engineering design. The results: higher filtration rates, reduced moisture content and process stability. Say hello to efficient, high-performance filtration with Metal7!

Key Benefits:

- Anti-wear and self-lubricating coatings on critical components.

- Significantly longer service life.

- Minimal maintenance requirements.

- Optimized design to avoid leaks and pressure drops.

- Production of filter cake with constant moisture content, enabling stabilization of the agglomeration process.

- Production of filter cake with reduced moisture content, enabling lower energy consumption on the firing process (drying zone).